What are the Structural Advantages of the ‘I’ shape in Beams?

WHAT ARE I-BEAMS?

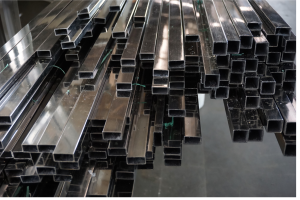

Engineers have long known that picking the right materials and shapes can make or break a structure. The I-beam, that unmistakable piece shaped like a capital I, has become a real workhorse as a metal for construction. Take the galvanized square steel beam variant, for example. It shows in most cases how a tweak in design and a bit of metal treatment can upgrade a classic form.

Instead of scattering its weight all over, the I-beam puts most of it along its flanges, doing a surprisingly solid job of handling loads while using less material. This trick not only helps it stand up to bending and shear stress but also lowers overall construction costs. So, even as architects and engineers keep testing out new building techniques, the I-beam remains a testament that smart design goes a long way in creating sturdy structures.

STRUCTURAL IMPORTANCE OF I-BEAMS

I.The load-bearing capacity of I-beams

The structural integrity of buildings is based on the strength of the materials used. They have to handle loads in ways that aren’t always obvious. A structure’s safety comes from using materials that mix toughness with stability, and this is why choices like the I-beam catch the eye of modern construction.

The I-beam, with its shape that simply mimics the letter I, spreads the weight over its top parts and the connecting web, letting it cope with heavy forces without losing shape. Sometimes, these beams are coupled with galvanized square steel beam versions, which boost their resistance against natural wear, even if sometimes the pairing might seem a bit overdone.

It’s easy to see why, in the world of metal for construction, I-beams are the go-to: they’re light enough to handle diverse projects yet tough enough for everything from bridges to high-rise structures.

II. The efficiency of material use in I-beams

At the heart of an I-beam’s function is its knack for making the best use of materials while keeping things structurally sound. It spreads loads in a way that generally speaking, cuts down on extra material without letting strength drop. This design not only amps up its ability to bear loads but also shaves off needless weight, which is why many in construction favor it in a variety of projects.

In many cases, using metal formed as an I-beam lets engineers span great distances with fewer supports, streamlining the overall design process and often lowering costs. Plus, the galvanized square steel beam versions tend to resist corrosion, helping extend the life of the framework. These distinctive features combine to show why the I-beam remains a key player in modern construction, a pretty neat blend of performance and resource efficiency.

III. The versatility of I-beams in construction applications

Structural parts shape how well a project runs and how long it lasts. The I-beam is not just another piece of metal for construction but one with a shape that, in many cases, beats other forms when it comes to bearing loads.

You’ll see these beams popping up everywhere, from small homes to sprawling commercial spaces, mainly because their strength-to-weight mix makes weight distribution easier to handle. Using metal in the form of I-beams tends to offer smart, practical answers for modern issues like seismic resilience and designing long spans without extra fuss.

This flexible, sometimes surprising, nature of I-beams is a big reason why many engineers and architects pick them as a reliable, efficient solution, even if, occasionally, they pair them with other approaches.

CONCLUSION

The I-beam, especially when it's galvanized square steel beam, truly packs a punch in terms of structural perks. In big construction projects, this lightweight yet tough build makes all the difference, since those resilient steel beams keep the entire structure solid. You know, another important feature is their adaptability. The I-beams can be arranged in lots of different ways, fitting neatly into various architectural styles. All in all, the efficient performance of these beams often explains why engineers and architects, who generally look for strength and dependability in their materials, tend to make them their first choice.

For metal distribution, fence hardware, manufacturing, and fabrication, check out Bobco Metals.