Why Aluminum Flat Bars, Channels, and Square Tubing Are Essential in Modern Manufacturing

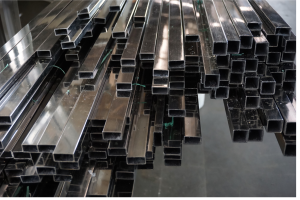

Aluminum has become a cornerstone of modern manufacturing, and for good reason. Known for its lightweight strength, corrosion resistance, and versatility, aluminum profiles such as flat bars, aluminum channels, and aluminum square tubing have wide-ranging applications across numerous industries. At Bobco Metal, we understand the crucial role these materials play in today's production processes, and we're here to help you understand why they are indispensable in modern manufacturing.

The Key Advantages of Aluminum Profiles in Manufacturing

1. Lightweight Yet Strong

One of aluminum's primary benefits is its high strength-to-weight ratio. This makes it ideal for applications that require strong materials without the added weight of steel. Aluminum flat bars, for example, offer substantial structural support in construction and are particularly valuable in industries like aerospace and automotive, where reducing weight is essential for efficiency and fuel economy.

2. Corrosion Resistance

Aluminum is naturally resistant to rust and corrosion, making it suitable for indoor and outdoor applications. Aluminum channels are frequently used in areas exposed to the elements, such as building exteriors or coastal constructions, as they can withstand moisture and salty air. This corrosion resistance extends the lifespan of products and reduces the need for maintenance, translating to cost savings for manufacturers.

3. Versatile Applications

The versatility of aluminum square tubing makes it popular in industrial and consumer applications. Its hollow structure provides rigidity while remaining lightweight, which is valuable in the construction, automotive, and furniture manufacturing industries. From framing structures to creating custom designs, aluminum square tubing's versatility makes it an essential component across sectors.

How Aluminum Profiles Contribute to Sustainability

Modern manufacturing increasingly prioritizes eco-friendly practices, and aluminum is a highly sustainable material. It is fully recyclable without losing quality, so manufacturers looking to reduce their environmental impact frequently turn to aluminum. When manufacturing products with aluminum flat bars, aluminum channels, or aluminum square tubing, companies like Bobco Metal provide durable and cost-effective solutions and support environmentally conscious manufacturing processes.

Precision and Ease of Fabrication

Aluminum's malleability makes it easy to shape, cut, and weld, allowing for precision in complex designs. Aluminum flat bars, channels, and square tubing are adaptable to custom sizes and shapes, making them ideal for specialized manufacturing needs. This flexibility is essential for industries that require intricate design elements, such as electronics, where aluminum components contribute to compact and efficient devices.

Popular Uses in Manufacturing

- Construction and Architecture

- In construction, aluminum channels and square tubing are used for framing and structural support, while flat bars can be found in stair railings, window frames, and doors. Aluminum's aesthetic appeal also makes it popular in architectural applications, where its clean, modern appearance is highly valued.

- Transportation

- The transportation sector relies on aluminum profiles to reduce vehicle weight, enhance fuel efficiency, and reduce emissions. Aluminum flat bars are used in everything from aircraft wings to automotive frames, providing strength without excess weight.

- Electrical and Electronics

- Aluminum's excellent conductivity makes it a natural choice for electronics. Aluminum channels are frequently used for housing electrical wires, while square tubing and flat bars contribute to frames and housings for various devices.

- Furniture and Consumer Goods

- Aluminum's versatility and appearance make it popular in the furniture and consumer goods industries. Many modern furniture designs incorporate aluminum square tubing for clean lines and lightweight frames, while flat bars and channels are used in a range of home products, from shelving to kitchen fixtures.

Conclusion

In today's fast-evolving manufacturing landscape, durable, versatile, and sustainable materials are in high demand. Aluminum flat bars, channels, and square tubing meet these needs, offering unparalleled benefits across various industries. At Bobco Metal, we provide high-quality aluminum profiles tailored to meet the unique demands of modern manufacturing. Whether you're in construction, automotive, or consumer goods, our aluminum products are designed to support innovation and efficiency.

FAQs

Q: Why is aluminum preferred over steel in specific applications?

Aluminum is lighter than steel, making it ideal for applications where weight reduction is critical, such as automotive and aerospace. Unlike steel, aluminum is also naturally corrosion-resistant.

Q: What are the primary uses of aluminum flat bars?

Aluminum flat bars are versatile and used in construction, automotive, and consumer products. They provide support and structure while remaining lightweight.

Q: How does Bobco Metal ensure the quality of its aluminum profiles?

At Bobco Metal, we source top-grade aluminum and adhere to strict quality standards to deliver reliable, durable aluminum products that meet the demands of modern manufacturing.With its unmatched benefits, aluminum continues to play an essential role in creating sustainable, efficient, and innovative products. Regarding reliable aluminum flat bars, channels, and square tubing, Bobco Metal is your trusted partner in modern manufacturing.